There’s been a lot of discussion recently about the dangers of connecting automation equipment to networks, and yet there are significant pressures to do so. Of course, I don’t ever think that you should take a PLC and put it on an internet accessible IP address, but it’s certainly common practice to connect industrial automation equipment to internal LANs to facilitate data collection. People in the front office need to push production planning information down to the production floor, and they need real-time data on what’s going on (not to mention for historical data logging, historians, etc.).

It’s all too common to throw a PLC on the same network as your front office, and I’ve seen it blow up. What happens is something invariably goes wrong on the office network (someone plugs two ports together on the switch in the boardroom, or someone brings in an infected music player and plugs it in, or the DNS server at head-office goes down and the local DNS doesn’t work correctly… I’ve seen a lot). However, you want your machines to keep going when this happens.

This is all made worse now that (a) industrial automation equipment is more commonly based on off-the-shelf commodity hardware and software (e.g. windows PCs) and (b) the people writing malware can actually spell PLC now. Up to this point there’s been some form of security through obscurity.

If you have a local IT staff that’s on the ball, you really should be getting them to handle the network layout. On the other hand, if you’re in a small facility with limited resources, there’s a lot you can do by making some simple design choices that will go a long way towards improving the reliability and security of your systems.

Most automation cells now come with an Ethernet switch already built-in. Typically this is an industrial spec. DIN-rail mounted one. It’s not fancy, but it’s supposed to survive in a panel. These Ethernet switches are there to connect your PLC to your HMI, and increasingly to connect your PLC to Ethernet-based I/O like Ethernet/IP, etc. The common (and wrong) thing to do is to drop a network cable from your plant network to your panel and plug it right into this Ethernet switch. This creates some technical problems right off the bat:

The automation devices typically have fixed IP addresses (I personally prefer this because it means these devices aren’t dependent upon an external DNS or DHCP server – two less dependencies are good). Chances are that these IP addresses won’t work on your plant network, so you have to manage those IPs at the plant level. You’re opening yourself up to someone with the wrong IP on their laptop pouncing on your PLC’s IP address, and then bam, your machine is down.

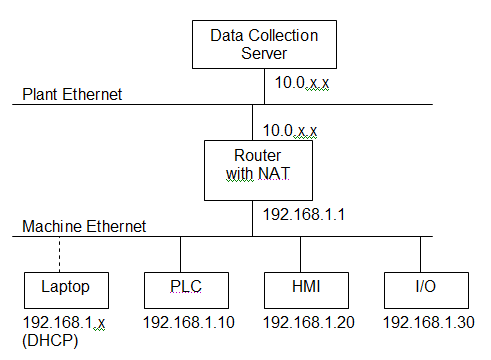

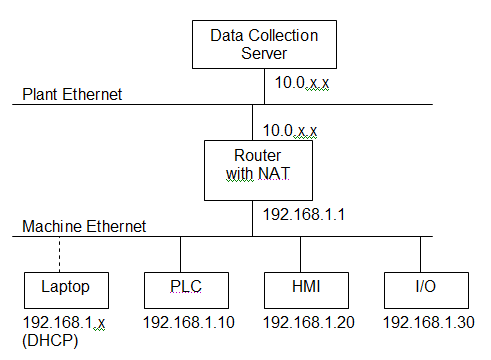

A much better way is to place some kind of Router with NAT between the plant network and the machine’s Ethernet Switch:

Now if you’re just a little manufacturer with two machines out back and your data-collection link isn’t critical, you can probably get away with one of those home routers from Best Buy that you’d use to connect your laptop and your desktop at home to your cable modem. Note that it doesn’t need to be wireless, and you’re probably better off if it isn’t. The way you hook it up is to connect the Internet (Uplink) port on the router to the plant network and run a cable from one of the ports on the LAN side to the existing Ethernet switch in the machine. If your data needs to be a bit more reliable, consider buying some kind of Cisco router with NAT capability (but you’ll be going from the $50 range to many hundreds of dollars – your choice).

Now, when you configure it, you want to make sure that you turn off the port forwarding function, the DMZ function, disallow remote administration, and block all anonymous internet traffic (these should be default settings, but it’s good to check). Also, make sure the router’s local IP address doesn’t conflict with the PLC’s and HMI’s, and make sure they have the same subnet. Typically you’ll want to either turn off DHCP on the local side, or limit it to a range that won’t conflict with the fixed IPs. DHCP is handy when you connect your laptop to the programming port. Now what you’ve done is made it somewhat invisible from the plant side. Some piece of malware scanning for devices on your plant network should just see a black hole.

Now on the PLC side, you can now initiate a connection to the data collection server even though the data collection server can’t connect to the PLC (in the same way that your home computer can connect to Google, but Google can’t get to your PC – theoretically). Note that a piece of malware on your data collection server or on one of the routers/switches in your plant network could intercept this communication, and own your PLC, but at least you’ve significantly reduced the surface area of attack. Not perfect, but reasonable at this time, depending on the sensitivity of your equipment. I’m assuming you’re not enriching uranium or providing drinking water to my community.

(I’m going to be talking specifically about Allen-Bradley products now – sorry.)

So how do you get the data from the PLC to the data collection server? In the old days you’d have some software on the server like RSSQL, and it used a product like RSLinx Enterprise and as far as I know, it initiated the connection to the PLC. That won’t work in this case. Sometimes you’d throw an OPC server in there, and have some kind of historian that would log tags to a database. That OPC server, obviously, needs to be able to initiate a connection to the PLC. To use a router with NAT, you’d need to port-forward from the router to the PLC (or to the OPC server if it was inside the machine network). That’s undoing a lot of our protection.

What you need to do is initiate the connection from the PLC, and have the Data Collection computer act as a Server. One way to do this is with a 3rd party Ethernet card, like this MVI56-GEC card from Prosoft for the ControlLogix line. I have used that in the past to connect to a server, but it involves a lot of ugly PLC coding. It’s your only option if you have to conform to someone else’s protocol though.

If you just want to write data directly into a SQL database, there are 3rd party products that will let you do this (basically a SQL Server connector card).

But there is an option without buying any new hardware. The ControlLogix/CompactLogix lines can send Unsolicited CIP messages, and you can find products that can receive these messages in the PC world, like CimQuest’s NET.LOGIX product. It can act as a server and receive data directly from the PLC – either individual tags, or even arrays of UDTs. The code on both ends is relatively simple, so all you have to pay for is the NET.LOGIX runtime license, which is cheaper than the hardware alternatives. Note that you can also do this with PLC5 and SLC500 devices, though there’s some more effort involved.

I hope that’s enlightening. This is by no means a perfect solution, but it’s reasonable for now. It doesn’t plug the laptop hole (the programming laptop is probably still your #1 vector for malware to get into your machine network). It’s susceptible to man-in-the-middle attacks between the router and the data collection server. It’s susceptible to exploitable bugs in the router’s firmware. Beware and use your own judgement.