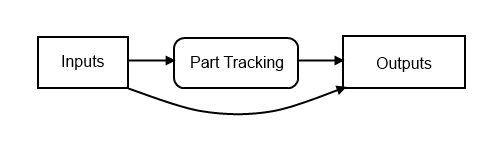

There are many ways to visualize your program at a higher level. Take a look at this model for a second:

I tend to focus on Part Tracking as a core part of my programming work. You can think of the part tracking as the PLC’s internal model of the outside world. That is, it’s the world that can’t be sensed directly by the inputs. In some cases the part tracking information can be used in spite of the current state of the inputs. Let me explain.

Imagine a work cell where a robot places a part in a fixture, a nut feeder feeds a nut onto the part, and then a weld gun extends from the top, and welds the part.

There are various places where we may place sensors in this situation, and you sometimes don’t have much control of it. Perhaps there’s a sensor in the fixture detecting that the part is there, but sometimes the mechanical engineers can’t find a place to fit one in. Sometimes the robot gripper has a sensor (or sometimes we use vacuum sensors to detect a part we’re picking up with vacuum). Perhaps neither is the case and we just know the robot has a part because we knew there was one in the infeed fixture and we know the robot went there and gripped, so we just assume it’s there.

Part Tracking gives you a way to remove some of this uncertainty. Create a memory bit (M1) to indicate there’s a part in the robot gripper. If the robot gripper moves to the fixture position and opens, then clear memory bit M1 and set memory bit (M2) indicating there’s a part in the fixture.

Keep this part tracking logic separate from your fault logic (so your part tracking logic is predictable and similar from project to project). If you happen to have a sensor in the fixture, create a separate rung that seals in a fault if the M2 bit is on and the fixture part present sensor is off, and use a delay timer of 100 ms or so just to allow for a sensor blip. Make sure the fault stops the cell. In this case I typically require the operator to go into the HMI and manually clear the “ghost” part in the fixture (i.e. clearing the M2 bit) before they can reset the fault. That way I know that they know the part really is missing. Likewise, a second fault rung seals in if M2 is off, but the sensor indicates a part.

Now as I said, sensors can sometimes be unreliable, and nowhere is this more common than in a weld cell. The high magnetic field generated by the weld current, and the weld expulsion splattering around is a surefire way to mess with both inductive proxes and optical sensors. Separating part tracking from sensors gives you a way to deal with this. For instance, when the welder is firing, mute out the faults so they don’t trigger if the sensor suddenly reads incorrectly.

To put it another way, use your part tracking to make decisions, and use the sensors to validate the part tracking, but only at times when you’re sure of their validity.

Furthermore, you can use inputs to initiate actions without requiring them to be on for the entire duration of the action. For instance, you can require that the fixture sensor is on to indicate a part is present before you fire the welder, but you can seal in the Fire_Welder bit around the sensor contact so the sensor can flicker after the output turns on without causing the output itself to flicker on and off.